Polyurea Coatings for Cistern Tanks

How Polyurea Fits the Real Conditions Inside Cisterns

Most tanks aren’t built in a lab. They sit under soil, behind walls, or out in open air where temperature and pressure change daily. When concrete sweats or steel shifts, the liner inside must move with it. Polyurea doesn’t resist that motion—it accepts it. That characteristic changes the way cisterns behave over time. Coatings that crack or peel under tension often fail at corners or seams. Polyurea, applied in one continuous membrane, doesn’t give tension a single point to start. The result is a coating that adjusts without breaking and seals without relying on perfect stillness from the surface beneath it.

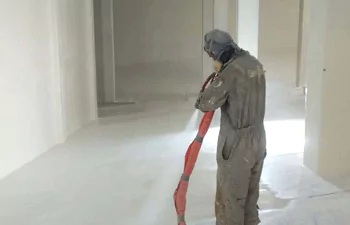

Curing Fast Doesn’t Mean Skipping the Details

Polyurea sets within seconds. That speed allows fast return to service, but it also narrows the installer’s margin for error. The surface beneath the spray still matters. A coating sprayed onto dust, moisture, or old buildup may fail—not because of the polyurea itself, but because of what it tried to hold onto. That makes preparation the real foundation of the job. Once applied, polyurea holds fast. It bonds tightly to concrete, steel, fiberglass, or other cured materials. The cured layer resists abrasion, handles water pressure, and flexes without separating from the tank wall. That combination makes it an effective match for tanks where age or environment would otherwise limit options.

Water Storage Requires More Than Just Containment

A cistern liner doesn’t just store water. It protects water from exposure, evaporation, and contamination. In tanks holding potable reserves, the coating must meet safety standards while also standing up to regular disinfection and cleaning. In irrigation systems, the coating must resist chemical additives and sediment buildup. Polyurea meets these needs because it doesn’t absorb water or break down with routine cleaning. It also doesn’t crack under sudden changes in temperature or tank load. Once bonded, it maintains a tight seal across pipe entries, joints, and floor-to-wall transitions without forming gaps where water can collect.

Design Meets Use, Not Just Shape

Every cistern has its own history. Some were poured decades ago with irregular floors and patched outlets. Others were prefabricated and installed with uniform geometry. Polyurea doesn’t need a perfect surface. It needs a surface that’s been understood. That’s where the coating shows its strength—not just in application, but in how it adapts to tanks that already carry the scars of years in service. The coating molds to each curve, each rise, and each imperfection, becoming part of the structure rather than sitting on top of it. Over time, this compatibility proves more important than any technical spec.

The Right Match for the Way Tanks Actually Age

Cisterns age from the inside out. Their wear comes from stored water, vapor movement, and changing pressure—not just from sun or surface damage. Polyurea protects from within, by sealing the wall and stopping the slow erosion that undermines structural integrity. When applied properly, it allows a tank to keep serving without the need for full reconstruction or liner replacement. That benefit matters more than a strong headline. It gives quiet assurance that water will stay where it’s meant to stay—inside the tank, unbothered by movement, time, or use.