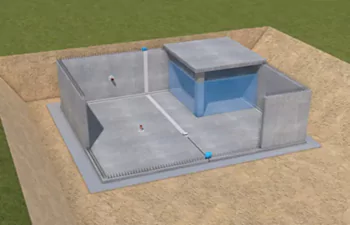

How to Properly Build a Concrete Cistern

The Ground Determines the Outcome

Before concrete is poured or forms are set, the ground beneath the cistern must stay still. Soil that shifts or drains poorly changes the shape of the tank long after the concrete hardens. That kind of movement doesn’t happen quickly. It shows up months later—when minor settling forms cracks at corners or along seams. Building a cistern begins with understanding where it sits. That includes how water moves through the surrounding earth and how pressure builds from above and below. The most durable cistern holds its shape because the ground beneath it stops moving first.

Formwork Shapes Strength, Not Just Size

The forms used for casting a cistern define more than its dimensions. They decide how the concrete cures and where stress collects. If the forms fail to hold shape, even slightly, the walls bow or taper. Once poured, the concrete will take that curve forever. Every bulge becomes a pressure point. Every sharp angle, if left untreated, becomes a weak corner. Proper spacing, tight joints, and strong reinforcement keep the concrete uniform. Rebar supports the walls, but only if it’s placed to intercept load paths—not just added as a layer. Where water pushes hardest, the reinforcement must already be there.

The Mix Must Follow the Function

Not all concrete works in tanks. A cistern holds water, not traffic. The mix must be dense enough to stop seepage but flexible enough to cure without excessive shrinkage. If it dries too quickly, microcracks open before the walls ever meet water. If it sets too slowly in cold or wet conditions, the surface stays weak. Additives help, but only if they match the job—not just the weather. What matters more is that the concrete doesn’t lose its water before it finishes its chemical reaction. A cistern made for storage needs its walls to cure slowly and evenly.

Curing Shapes Long-Term Integrity

After the pour, the structure needs time. Concrete gains strength through hydration. If that process is interrupted—by sun, wind, or premature form removal—the surface hardens unevenly. The result doesn’t always show immediately. In time, though, weak layers begin to flake. Water finds the difference and enters through capillaries that should have closed during curing. To prevent that, curing compounds or covers must stay in place until the concrete reaches enough internal strength to resist evaporation. A good tank doesn’t just dry—it cures.

Coatings Don’t Fix What Wasn’t Built Right

Once cured, the concrete will carry any flaws with it. That’s why coatings can only succeed if the surface below them makes sense. If cracks have already opened or if corners weren’t finished well, even the best liner will struggle to stay attached. Polyurea and other coatings follow the wall’s shape with precision. That precision reveals what the original build got right—and what it didn’t. So building the cistern well from the start remains the best way to make coatings last. Clean forms, good mix, steady curing, and grounded placement work together to ensure the structure stays whole.

Final Thought

A concrete cistern holds more than water. It holds time, weight, and the quiet effects of every season. When built properly, it stores water for decades without asking much in return. But that only happens when each step—from soil prep to form removal—respects the pressures that tank will face. Once finished, the tank should do its job without need for attention. Not because it was overbuilt, but because it was built with care. That’s what makes a cistern work—not just concrete, but everything that came before it set.